- 1.Certified by ISO9001,14001,18001 quality management system.

- 2.Manufacturing by Germany advanced technology and process.

- 3.Passed mining products safety sign audit assessed.

- 4.High quality raw material selection made bearing work lifetime more than 50000 hours.

- 5.Resistance of product rotating is 30% lower than that as natiinal standards, which can save 40% power consumption per hour.

Tereck Mining Technology Co.Limited

- HOME|

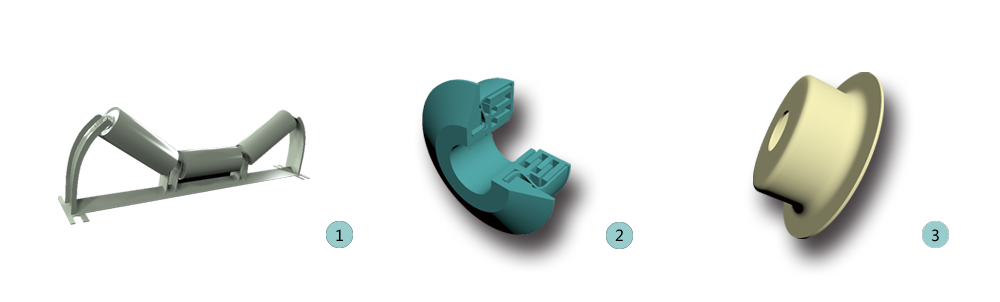

1.Bracket idler use hand-held welding, and then painting after surface treatment. That will ensure idler's precision and strength to make idler long service life and good outlook.

2.The seal arrangement selects non-contact multiple labyrinth waterproof design. The water proof index S 130g in water-spray and<.200g in soak test and the rotation drag less than 2.31N, which performance obviously better than normal seal. All seals are made from PA/A BS. It uses top lithium-based g rease to fill in seals and would from multipleseal with snap ring, housing button hole, roller shaft and grease in andh gap, which increase seal performance and inner anti-corrosive, so that solve roller's "breathe problem“in working.(It means roller tempera-ture rises inoperation, innergas expands; and the temperature decrease in non-working, inner gap shrinkage in negative pressure. inner gap shrinkage in will inhale out gas and liquid into roller inside if in normal seal, so that will in,crease inner condens water and make the grease in-effective to destruct the roller environment then lead to roller inner corrosive.

3.Housing is completed through sequential punching on imported superior steel sheet(S PCC). Finished housing features even thick- ness, good surface, precise measure -ment andconsistency. Inner radius of housing completed is in conformity with designed value and rough- ness required by bearing and rube. The surface of housing is phosphated and de- greased to improve cohesion of painting film.

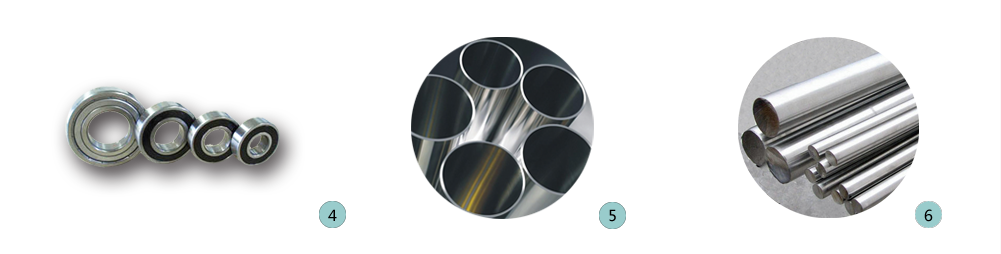

4.roller bearing uses double seal(zz) deep grooveball bearing with C3 clea rance. Volume oflithium g rease filled inside ranges from l/2 t0 2/3, which secrues the ling service life.

5.Customized roller tubes are purchased from famous manufacturer. The tubes fo r roller must be those with excellentdymanic& static and free from inner burs.

6.We has strict control over tolera nce of shaft dimension and surface quality. The othertechnical indicator should be no less competitive than that of G B/T3078-94 We uses the shaft which are made of cold-drawn bright round steel, which is superior in corrosion resistance and stiffness resistance and stiffness.The service life can be well secured and prolonged.

CopyRight © 2021 Tereck Mining Technology Co.Limited all rights rerserved 沪ICP备15031775号-1